Mica Flakes Revolutionizing the Rubber Industry Comprehensive Guide to High-Performance Fillers

Mica is the general name of mica group minerals. It is the aluminosilicate of potassium, aluminum, magnesium, iron, lithium and other metals, all of which are layered and monoclinic. The crystal is pseudohexagonal lamellae or plate like, occasionally columnar. The lamellar cleavage is very complete, with glass luster and elastic sheet. The refractive index of mica increases with the increase of iron content, from low protrusion to medium protrusion. The variety without iron is colorless in the flake. The higher the iron content, the darker the color, and the more polychromatic and absorptive.

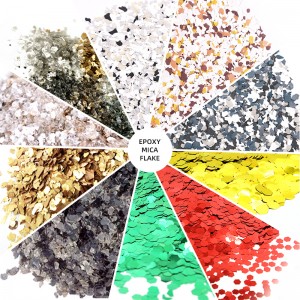

Mica flake size: 6-10mesh, 10-20mesh,

Mica powder: 200mesh, 325mesh, 600mesh, 800mesh, 1250mesh, 2000mesh, 3000mesh and 5000mesh.

Application

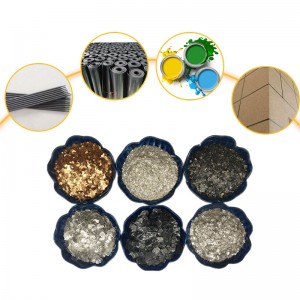

In the industry, biotite mainly uses its insulation and heat resistance, as well as acid resistance, alkali resistance, compression resistance and peeling resistance, as the insulation material of electrical equipment and electrical equipment; secondly, it is used to manufacture the windows and mechanical parts of steam boilers and smelting furnaces. Mica chips and mica powder can be processed into mica paper, and can also replace mica sheet to produce various low-cost and uniform thickness insulating materials.

Muscovite is the most widely used in industry, followed by phlogopite. It is widely used in building materials industry, fire fighting industry, fire extinguishing agent, welding rod, plastic, electrical insulation, paper making, asphalt paper, rubber, pearlescent pigment and other chemical industries.

Ultrafine mica powder is used as functional filler for plastic, paint, paint, rubber and so on, which can improve its mechanical strength, enhance toughness, adhesion, anti-aging and corrosion resistance.

Package