-

Translucent Mica Flakes As Plastic Reinforcement For Injection Molded Parts Household Plastic Products And Industrial Plastic Components Plastic Reinforcing Filler

Translucent mica flakes, a versatile and highly valuable material, have emerged as a crucial plastic reinforcing filler across a diverse range of applications. From injection molded parts to household plastic products and industrial plastic components, these flakes play a pivotal role in enhancing key properties such as strength, heat resistance, and dimensional stability. Sourced predominantly from the rich mica deposits of Guizhou and Shanxi provinces in China, these regions are renowned for producing high-quality, translucent, and robust mica flakes. The mica flakes undergo a meticulous processing phase aimed at improving their dispersion within plastic melts, ensuring a uniform and effective reinforcement throughout the finished products.

Injection Molded Parts

In the realm of injection molded parts, which encompass a wide array of components including plastic gears and electrical connectors, the addition of translucent mica flakes yields significant improvements in tensile strength. The unique layered structure of the mica flakes allows for a strong bond with plastic polymers. This strong interconnection acts as a safeguard, preventing parts from succumbing to breakage under stress or deforming under bending forces. This property is of utmost importance for components utilized in household appliances, such as washing machine parts, where consistent performance is essential for the smooth operation of the appliance. Similarly, in industrial machinery, where components are subjected to rigorous working conditions, the enhanced strength provided by mica flakes ensures the reliability and longevity of the equipment.Household Plastic Products

Household plastic products, including items as common as food storage containers and kitchen utensils, greatly benefit from the inclusion of mica flakes. One of the primary advantages is the significant enhancement in heat resistance. With mica flakes integrated into their composition, these products can endure elevated temperatures, such as those encountered in microwave ovens or when exposed to hot water. This heat resistance not only prevents warping but also ensures that the products do not release any harmful substances.Industrial Plastic Components

For industrial plastic components, such as pipes and conveyor belts, the dimensional stability imparted by mica flakes is a game-changer. During the cooling process of plastic manufacturing, shrinkage is a common issue that can lead to components not fitting together properly or deforming over time. Mica flakes effectively mitigate this problem by reducing plastic shrinkage, ensuring that industrial components fit precisely and maintain their shape throughout their service life. Additionally, mica flakes enhance the chemical resistance of plastic components. This property makes plastic pipes highly suitable for transporting a wide variety of industrial fluids without the risk of degradation, thereby extending the lifespan of the pipes and reducing maintenance costs.Chinese Manufacturers’ Role

Chinese manufacturers of translucent mica flakes are not only suppliers but also partners in the plastic production process. They offer comprehensive technical support to plastic producers, providing valuable advice on determining the optimal flake loading levels. Striking the right balance between strength and flexibility is crucial for the performance of plastic products, and Chinese manufacturers assist in achieving this equilibrium.In terms of production capabilities, Chinese facilities are equipped with state-of-the-art grinding technology. This advanced equipment enables the production of mica flakes with a consistent particle size, which is essential for achieving uniform reinforcement in plastic products. The consistency in particle size ensures that the properties of the plastic are evenly distributed, resulting in more reliable and high-performance end products.Furthermore, China’s extensive and efficient shipping infrastructure, with major ports like Shenzhen and Qingdao, facilitates the global distribution of these mica flakes. This enables plastic manufacturers around the world to access high-quality Chinese mica flakes, thereby supporting the production of durable and high-performance plastic products across various industries. Whether it’s in the automotive sector, electronics industry, or consumer goods manufacturing, the availability of Chinese mica flakes has contributed significantly to the advancement of plastic product quality and performance.In conclusion, the utilization of translucent mica flakes sourced from China’s Guizhou and Shanxi provinces has revolutionized the plastic manufacturing industry. Their unique properties and the support provided by Chinese manufacturers have enabled the creation of plastic products with enhanced strength, heat resistance, and dimensional stability, meeting the diverse and demanding requirements of modern applications. -

Mica Flakes Revolutionizing the Rubber Industry Comprehensive Guide to High-Performance Fillers

Mica flakes, with their distinctive lamellar structure, exceptional chemical stability, and remarkable compatibility with rubber matrices, have firmly established themselves as high-performance functional fillers in the rubber industry. Unlike conventional fillers such as carbon black or calcium carbonate, mica flakes offer a unique combination of mechanical reinforcement, weather resistance, and dimensional stability, making them the ideal choice for rubber products operating in harsh environments, including automotive seals, industrial rubber hoses, and conveyor belts.

In the realm of automotive rubber seals, including door seals, window seals, and engine gaskets, mica flakes play a pivotal role in enhancing tear resistance and compression set performance. These seals are subjected to frequent mechanical stress, extreme temperature fluctuations ranging from -40°C to 120°C, and prolonged exposure to UV radiation, factors that can cause ordinary rubber seals to crack, harden, or lose elasticity over time.

The addition of 8%-15% of high aspect ratio mica flakes, with a particle size of 30-80 μm and an aspect ratio of ≥100, to ethylene-propylene-diene monomer (EPDM) rubber yields impressive results. The tear strength of the rubber increases by 40%-60%, while the compression set rate, measured after 70 hours at 100°C, drops significantly from 35% to 15%. A leading automotive parts manufacturer in Germany conducted extensive tests using our mica flakes in EPDM door seals. The results were remarkable: the seals maintained their elasticity and sealing performance for 500,000 opening and closing cycles, compared to just 300,000 cycles for seals without mica flakes. This extended service life not only reduces maintenance costs for vehicle owners but also enhances the overall reliability of automotive products.

For industrial rubber hoses used in the transfer of chemicals, oil, and water, mica flakes are instrumental in enhancing chemical resistance and pressure resistance. These hoses frequently come into contact with corrosive media and must withstand high internal pressures of up to 10 MPa. Mica flakes, with their impermeable lamellar structure, form an effective barrier within the rubber matrix, reducing the penetration of chemicals by 50%-70%.When added to nitrile rubber (NBR) hoses at a dosage of 10%-20%, mica flakes significantly increase the burst pressure of the hose by 25%-35% and extend its service life in oil transfer applications from 1 year to 2-3 years. A chemical plant in the Netherlands put our mica-reinforced NBR hoses to the test in the transfer of 20% concentrated sulfuric acid. The results were conclusive: after 12 months of continuous use, the hoses showed no signs of swelling or leakage, whereas standard NBR hoses failed after just 4 months. Additionally, mica flakes improve the dimensional stability of rubber hoses, reducing shrinkage during vulcanization by 15%-25% and ensuring a precise fit with connectors.All our mica flakes meet stringent industry standards in terms of key technical indicators. The moisture content is ≤0.3%, ash content ≤0.5%, oil absorption ≤25 mL/100g, and they exhibit excellent heat resistance, remaining stable at temperatures of up to 600°C. Furthermore, our products comply fully with RoHS and REACH regulations, with heavy metal content well below global safety limits (lead ≤0.0005%, arsenic ≤0.0003%).When it comes to logistics, we prioritize the quality and integrity of our products. Our mica flakes are packaged in moisture-proof bags (25 kg/bag), featuring an inner polyethylene film and an outer kraft paper bag to prevent moisture absorption during sea transportation. We have established strong partnerships with leading shipping companies such as Maersk and COSCO, ensuring timely delivery to customers in Europe, North America, and Southeast Asia within 15-30 days. -

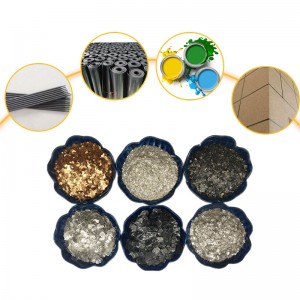

Mica powder for electrical appliances welding rods rubber plastics papermaking paints coatings product

Mica powder is derived from natural mica minerals (e.g., muscovite, biotite), processed via crushing and grinding to exfoliate their layered structure into fine particles. Mined globally (India, China, US), it features high dielectric strength (ideal for capacitors and electronics insulation), thermal stability (withstands 600°C+), and reflective properties. In cosmetics, ultra-fine grades create shimmer in makeup; in paints/plastics, it enhances weather resistance and mechanical strength as a reinforcing filler. Industrial uses include thermal insulation in appliances, fireproof coatings, and as a release agent in rubber manufacturing. Its chemical inertness and versatile particle sizes make it essential across electronics, construction, and personal care sectors.

-

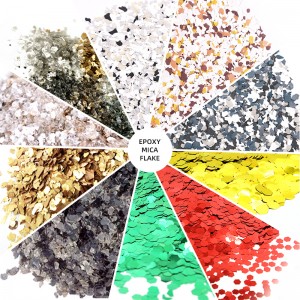

Wholesale 3-5mm Concrete Garage Epoxy Floor Coatings Resin Flake Colorful Mica Epoxy Floor Flake Chips

Type: mica powder, natural color mica flakes, colored mica flakes, synethic mica flakes.

Mica ore mainly includes biotite, phlogopite, muscovite, lepidolite, sericite, chloritite, ferro lepidolite and so on, and placer is a mixed mineral of mica and quartz. Muscovite and phlogopite are the most widely used minerals in industry. Lepidolite is an important mineral raw material for extracting lithium.

-

Factory price matte synthetic micas powder natural mica flakes for epoxy resin floor

Type: mica powder, natural color mica flakes, colored mica flakes, synethic mica flakes.

Mica ore mainly includes biotite, phlogopite, muscovite, lepidolite, sericite, chloritite, ferro lepidolite and so on, and placer is a mixed mineral of mica and quartz. Muscovite and phlogopite are the most widely used minerals in industry. Lepidolite is an important mineral raw material for extracting lithium.

-

China Manufacturer Natural Mica /Dyed Mica/Synthetic Mica Flakes with 40-80mesh

Type: mica powder, natural color mica flakes, colored mica flakes, synethic mica flakes.

Mica ore mainly includes biotite, phlogopite, muscovite, lepidolite, sericite, chloritite, ferro lepidolite and so on, and placer is a mixed mineral of mica and quartz. Muscovite and phlogopite are the most widely used minerals in industry. Lepidolite is an important mineral raw material for extracting lithium.

-

Mica Gold Silver Black Green Colors Mica, Professional Metallic Epoxy Mica Flakes Flooring for Sale

Type: mica powder, natural color mica flakes, colored mica flakes, synethic mica flakes.

Mica ore mainly includes biotite, phlogopite, muscovite, lepidolite, sericite, chloritite, ferro lepidolite and so on, and placer is a mixed mineral of mica and quartz. Muscovite and phlogopite are the most widely used minerals in industry. Lepidolite is an important mineral raw material for extracting lithium.

-

Mica Flakes Metallic Epoxy Mica Flakes Flooring Mica Colored Flakes for Sale

Type: mica powder, natural color mica flakes, colored mica flakes, synethic mica flakes.

Mica ore mainly includes biotite, phlogopite, muscovite, lepidolite, sericite, chloritite, ferro lepidolite and so on, and placer is a mixed mineral of mica and quartz. Muscovite and phlogopite are the most widely used minerals in industry. Lepidolite is an important mineral raw material for extracting lithium.

-

Wholesale natural mica flakes bulk golden mica flakes for epoxy floor coating

Type: mica powder, natural color mica flakes, colored mica flakes, synethic mica flakes.

Mica ore mainly includes biotite, phlogopite, muscovite, lepidolite, sericite, chloritite, ferro lepidolite and so on, and placer is a mixed mineral of mica and quartz. Muscovite and phlogopite are the most widely used minerals in industry. Lepidolite is an important mineral raw material for extracting lithium.

-

Wholesale Natrual Mica Flakes Price Muscovite Mica Epoxy Mica Chips Flake Colour Flakes for Epoxy Resin for coating

Type: mica powder, natural color mica flakes

Mica ore mainly includes biotite, phlogopite, muscovite, lepidolite, sericite, chloritite, ferro lepidolite and so on, and placer is a mixed mineral of mica and quartz. Muscovite and phlogopite are the most widely used minerals in industry. Lepidolite is an important mineral raw material for extracting lithium.

-

Golden mica flakes bulk metallic mica flakes with white gold black red green colors

Type: mica powder, natural color mica flakes

Mica ore mainly includes biotite, phlogopite, muscovite, lepidolite, sericite, chloritite, ferro lepidolite and so on, and placer is a mixed mineral of mica and quartz. Muscovite and phlogopite are the most widely used minerals in industry. Lepidolite is an important mineral raw material for extracting lithium.

-

Mica flakes wholesale color mica flakes factory direct sales white mica powder synthetic mica flake for epoxy resin

Type: mica powder, natural color mica flakes

Mica ore mainly includes biotite, phlogopite, muscovite, lepidolite, sericite, chloritite, ferro lepidolite and so on, and placer is a mixed mineral of mica and quartz. Muscovite and phlogopite are the most widely used minerals in industry. Lepidolite is an important mineral raw material for extracting lithium.