Professional China Glass Stone - China Factory Micro Glass Beads for Filler – Huabang

Professional China Glass Stone - China Factory Micro Glass Beads for Filler – Huabang Detail:

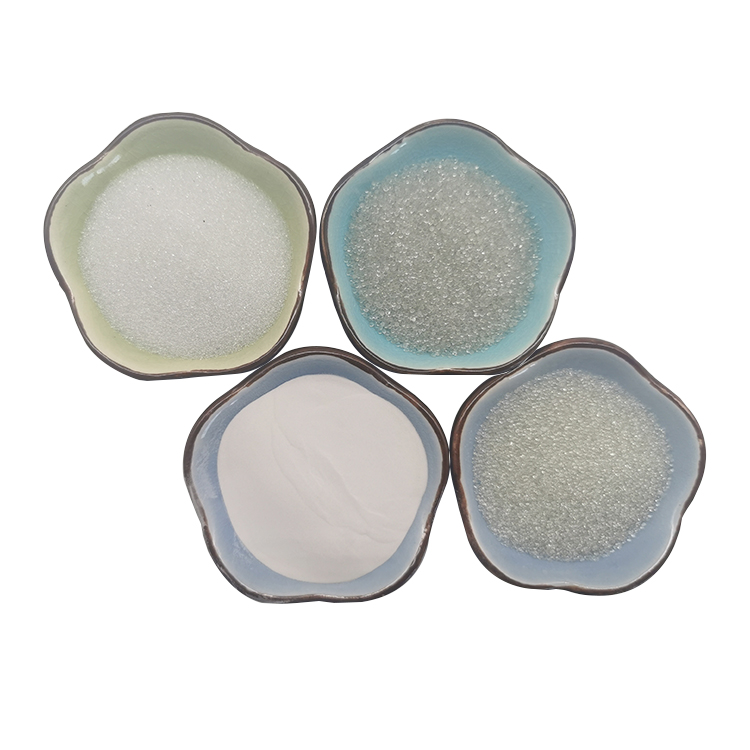

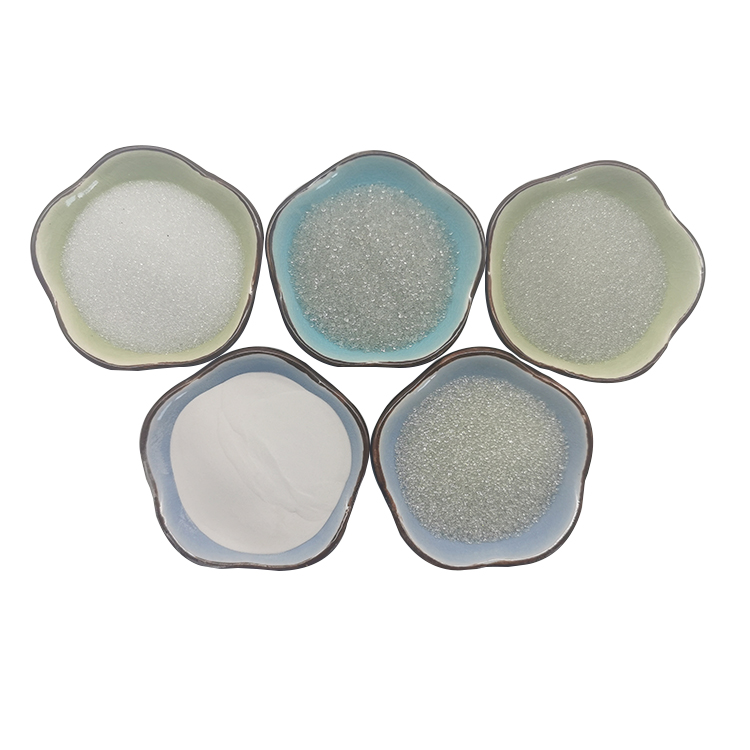

Glass beads

1. Light weight and large volume. The density of hollow glass beads is about one tenth of the density of traditional filler particles. After filling, it can greatly reduce the basis weight of the product, replace and save more production resins, and reduce product costs.

2. It has an organically modified (lipophilic) surface. Hollow glass beads are easy to wet and disperse, and can be filled in most thermosetting thermoplastic resins, such as polyester, epoxy, polyurethane, etc.

3. High dispersion and good liquidity. Since hollow glass beads are tiny spheres, they have better fluidity in liquid resin than flake, needle or irregular shape fillers, so they have excellent mold filling performance. What’s more important is that the small microbeads are isotropic, so there is no inconsistency in the shrinkage rate of different parts caused by the orientation, and the dimensional stability of the product is ensured without warping.

4. Heat insulation, sound insulation, insulation, low water absorption rate. The inside of the hollow glass beads is a thin gas, so it has the characteristics of sound insulation and heat insulation, and is an excellent filler for various heat preservation and sound insulation products. The thermal insulation properties of hollow glass microspheres can also be used to protect the product from the thermal shock caused by the alternating between rapid heating and rapid cooling conditions. High specific resistance and extremely low water absorption make it widely used in the processing and production of cable insulation materials.

5. Low oil absorption. The particles of the sphere determine that it has the smallest specific surface area and low oil absorption. The amount of resin can be greatly reduced during use, and the viscosity will not increase much even under the premise of high addition, which greatly improves the production and operating conditions. Increase production efficiency by 10% to 20%.

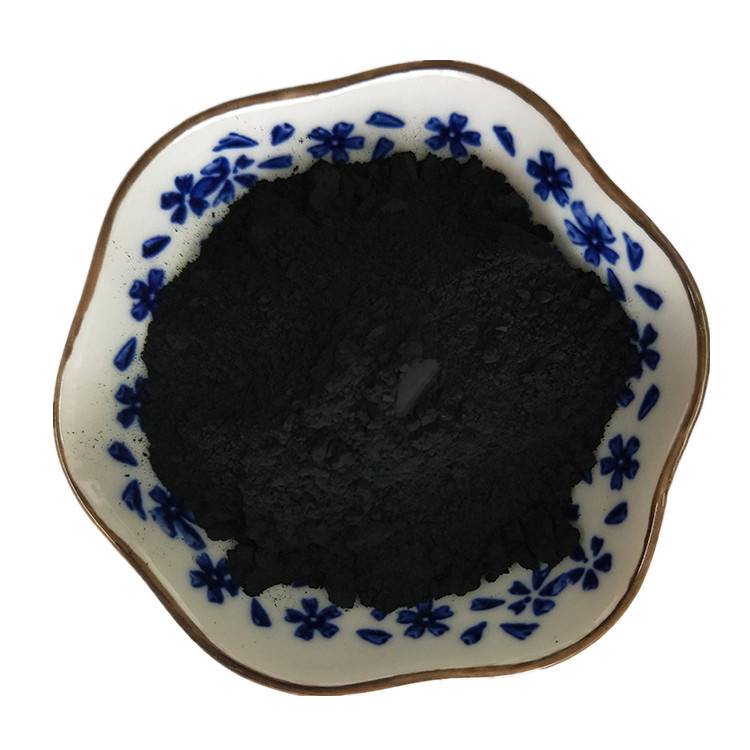

Product detail pictures:

Related Product Guide:

We are convinced that with joint endeavours, the small business between us will bring us mutual benefits. We could assure you products quality and competitive selling price for Professional China Glass Stone - China Factory Micro Glass Beads for Filler – Huabang , The product will supply to all over the world, such as: Sacramento, Slovenia, America, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We've been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.